Full 1

CUTTING & WELDING EQUIPMENTS

Cutting Equipment

CUTTING EQUIPMENTS

Top Features

- Cutting equipment includes plasma cutters, plasma cutting systems, CNC cutting systems, pipe cutting machines, structural steel fabrication, motion and shape cutting controllers, and genuine torch consumables for plasma torches.

Welding Equipment

MIG WELDERS

FLEXTEC® 650X MULTI-PROCESS WELDER WITH CROSSLINC™ TECHNOLOGY

Top Features

- Use with a wide range of available 3-phase input power

- Easy one-knob process selection

- Components designed to run cool for long life in high-temperature environments

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Power IND 250C

Top Features

- Lightweight and portable- easy to move and suitable for stacking

- Features Lincoln’s latest generation Inverter technology for maximum reliability

- Thermal overload protection is available for stable welding output under all demanding conditions

- Input – 50Hz, 3Phase

- Output – DC

POWERIND 400I

Top Features

- Light weight and portable- easy to move and suitable for stacking

- Features Lincoln’s latest generation Inverter technology for maximum reliability

- Thermal overload and single phasing protection for stable welding output under all demanding conditions.

- Input – 50H, Phase

- Output – CC/CV, DC

FLEXTEC 350X

Top Features

- Flexible – Compatible with across-the-arc, analog, digital or CrossLinc™ feeders

- CrossLinc™ Technology – Full functionality without control cables

- Simple – Streamlined operator panel minimizes setup time.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Flextec 500

Top Features

- Streamlined operator panel minimizes setup time

- Components designed to run cool for long life in high-temperature environments

- IP-23 is rated for use in harsh environments.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

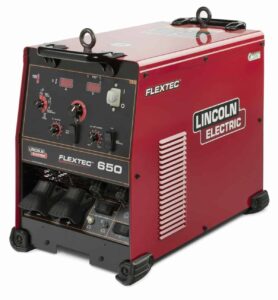

Flextec 650

Top Features

- Streamlined operator panel minimizes setup time

- Components designed to run cool for long life in high-temperature environments

- IP-23 rated for use in harsh environments.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Flextec 500P

Top Features

- Streamlined operator panel minimizes setup time

- Components designed to run cool for long life in high-temperature environments

- IP-23 rated for use in harsh environments

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Speedtec 505SP

Top Features

- Pulsed MIG process – great for low spatter, low heat input and out-of-position applications-makes virtually any operator a better welder!

- Premium welding behaviour on CV MIG & Stick welding.

- Variable inductance control.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Power wave C300

Top Features

- PowerConnect™ Technology (Patent-Pending) − Automatically adjusts to input power from 200-600V, 50 or 60 Hz, single phase or three phase.

- Tribrid™ Power Module − Exceptional welding performance with high power factor and efficiency.

- CheckPoint™ − A cloud-based data collection tool that allows customers to view and analyze welding data on almost any device – desktop, laptop, iPhone® or iPad®, Blackberry®, and others.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Power wave S350

Top Features

- PowerConnect™ Technology (Patent-Pending) – Automatically adjusts to input power from 200-600V, 50 or 60 Hz, single phase or three phase.

- Tribrid™ Power Module – Exceptional welding performance with high power factor and efficiency.

- CheckPoint™ – A cloud-based data collection tool that allows customers to view and analyze welding data on almost any device – desktop, laptop, iPhone® or iPad®, Blackberry®, and others.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Power wave S500

Top Features

- PowerConnect™ Technology (Patent-Pending) – Automatically adjusts to input power from 200-600V, 50 or 60 Hz, three-phase.

- Tribrid™ Power Module – Exceptional welding performance with high power factor and efficiency.

- CheckPoint® – A cloud-based data collection tool allows customers to view and analyze welding data on almost any device – desktop, laptop, iPhone® or iPad®, Blackberry®, and others.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Power wave S700

Top Features

- Wide Input Voltage Range – Set up operations almost anywhere (380-575 VAC, 3 phase, 50/60Hz voltage).

- Add AutoDrive® 19 Tandem modules to access waveform modes specifically designed for Synchronized Tandem MIG multi-arc applications.

- Low Operating Cost – Operates at a high 88% efficiency with a 95% minimum power factor (at rated output).

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

SAW WELDERS

Idealarc DC1000

Top Features

- 500 amp output connections – provide enhanced arc characteristics for low amperage submerged arc and MIG welding procedures.

- Single range control – for precise output control and easy operation.

- Terminal strip and output studs – for remote connections and cable.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Idealarc DC1500

Top Features

- Line voltage compensation for maintaining weld consistency, even with line voltage changes of ±10%.

- Fan-cooled with electronic and thermostatic protection from current overload and excessive temperatures.

- Windings and rectifiers are protected against moisture and corrosive environments.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Flextec 650

Top Features

- Streamlined operator panel minimizes setup time

- Components designed to run cool for long life in high temperature environments

- IP-23 rated for use in harsh environments

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Idealarc AC1200

Top Features

- Scott® connection taps standard for two AC welding heads operated in tandem.

- Rheostat adjusts the output settings while welding or at idle.

- Three output studs with overlapping ranges.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

POWER WAVE AC/DC 1000SD

Top Features

- 380 – 575 VAC, 50/60Hz Voltage Input – Offers the ability to be connected anywhere in the world.

- Easy to Parallel Machines or Run Multiple Arcs.

- 3-Phase Voltage Input – Eliminates the imbalance associated with transformer-based AC welding machines.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

STICK WELDERS

Invertec 270SX

Top Features

- op Features

- Robust, built for heavy environmental conditions

- Fully featured and user friendly control panel with digital display allows precise setting of welding current.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Invertec CC400 S Plus

Top Features

- High current range – 400amp, enable it can work with 6mm electrode

- S Plus model machine is installed with output choke and can weld cellulouse at vertical down.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

Invertec 400SX

Top Features

- Robust, built for heavy environmental conditions.

- Fully featured and user friendly control panel with digital display allows precise setting of welding current.

- Soft and Crisp mode multiple arc modes for different electrode types.

- Input – 50/60 Hz, 3Phase

- Output – CC/CV, DC

TIG WELDERS

Invertec 170TX

Top Features

- Advanced inverter technology for superior TIG performance

- Full function user-friendly control panel layout with graph and a numeric display make it easy to set all welding parameters

- Perfect TIG HF starting with pre-settable starting mode

- Input – 50/60 Hz, 1Phase

- Output – CC, DC

Invertec 270T

Top Features

- Excellent arc characteristics for a wide range of applications.

- Generator compatible, ideal for site use.

- HF and Lift TIG ignition.

- Input – 50/60 Hz, 3Phase

- Output – CC, DC

Invertec 170TPX

Top Features

- Advanced inverter technology for superior TIG performance

- Full function user-friendly control panel layout with graph and a numeric display make it easy to set all welding parameters

- Perfect TIG HF starting with pre-settable starting mode

- Input – 50/60 Hz, 1Phase

- Output – CC, DC

Invertec 220TPX

Top Features

- Advanced inverter technology for superior TIG performance

- Full function user-friendly control panel layout with graph and a numeric display make it easy to set all welding parameters

- Perfect TIG HF starting with pre-settable starting mode

- Input – 50/60 Hz, 1Phase

- Output – CC, DC

Invertec 270TP

Top Features

- Excellent arc characteristics for a wide range of applications.

- Generator compatible, ideal for site use.

- HF and Lift TIG ignition.

- Input – 50/60 Hz, 3Phase

- Output – CC, DC

Invertec 300TPX

Top Features

- Advanced inverter technology for superior DC TIG performance

- Full function user-friendly control panel layout with graph and a numeric display make it easy to set all welding parameters.

- Rugged construction: electrical safety (IP23), potted PC boards and optimum airflow reduce contamination to extend the equipment’s life in the harshest environmental conditions.

- Input – 50/60 Hz, 3Phase

- Output – CC, DC

Invertec 400TPX

Top Features

- Advanced inverter technology for superior TIG performance

- Full function user-friendly control panel layout with graph and a numeric display make it easy to set all welding parameters.

- Rugged construction: electrical safety (IP23), potted PC boards and optimum airflow reduce contamination to extend the equipment’s life in the harshest environmental conditions.

- Input – 50/60 Hz, 3Phase

- Output – CC, DC

Precision TIG 225

Top Features

- Easy-to-use operator interface – select mode, polarity and weld

- AC Auto-Balance® automatically adjusts for the optimal mix of cleaning and penetration when welding aluminum

- Enable the TIG pulser to minimize material distortion from excessive heat input

- Input – 50/60 Hz, 1Phase

- Output – CC, AC//DC

Precision TIG 275

Top Features

- AC Auto-Balance® automatically adjusts for the optimal mix of cleaning and penetration when welding aluminum.

- Or, take full control – adjust the AC Auto Balance® to increase or decrease cleaning action or penetration on aluminum

- Delivers the widest output range in its class with an amperage range of 2 to 340 amps

- Input – 50/60 Hz, 1Phase

- Output – CC, AC/DC

Precision TIG 375

Top Features

- ackle either end of the material thickness spectrum with the widest operating range in its class from 2 to 420 amps

- AC Auto-Balance® automatically adjusts for the optimal mix of cleaning and penetration when welding aluminum.

- Or, take full control – adjust the AC Auto Balance® to increase or decrease cleaning action or penetration on aluminum

- Input – 50/60 Hz, 1Phase

- Output – CC, AC//DC

Aspect 300

Top Features

- Advanced inverter technology for superior TIG performance

- Superb welding characteristics with TIG DC, TIG AC and Stick welding processes.

- Adjustable cleaning and penetration for perfect aluminium welding.

- Input – 50/60 Hz, 1Phase

- Output – CC, AC/DC

Aspect 375

Top Features

- Effortless arc control for the smoothest welds

- AC Auto-Balance® makes it simple by automatically providing the optimal mix of cleaning and penetration on aluminum

- Intellistart™ Technology provides soft starts on thin materials and hotter starts required on thicker materials

- Input – 50/60 Hz, 1Phase

- Output – CC, AC/DC